Functional doors

Special sizes are produced on short notice

We can set any standard thickness and any format.

The format can be expanded up to 3000 x 1220 mm.

Special Doors Products

Exterior Doors

Exterior doors are exposed to the weather and must be sufficiently resistant. They usually need additional technical functions such as fire and sound protection, burglar protection and thermal insulation.

The exterior doors include:

- House entrance doors

- Side entrance doors (e.g. cellar and garage doors)

- Arcade doors

Exterior doors are subject to CE marking in accordance with the DIN EN 14341-1 standard.

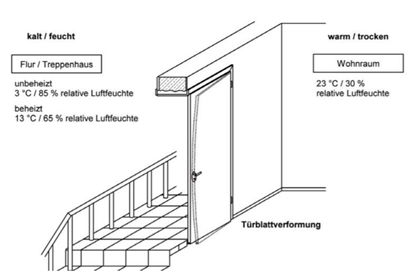

Differential Climate-stressed Doors

Doors made of wood / wood-based materials can deform under different climatic conditions. This deformation is due to the different shrinkage / expansion behavior of the materials used at different temperatures and humidity levels. By choosing a suitable door according to the climatic stress, you avoid hygrothermal-induced influences of the deformation and consequent damage such as leaky joints, reduced sound insulation and poor closing behavior.

Let H-Flachs design your door that is subject to a differential climate. We would be happy to send you additional information.

| Test Climate (according to DIN EN 1121) | Test Climate Classes (according to DIN EN 12219) | Interior Air Temperature | Interior Relative Humidity | Exterior Air Temperature | Exterior Relative Humidity | Twisting T | Lengthwise curvature B | Crosswise curvature C | Usage Recommendation |

|---|---|---|---|---|---|---|---|---|---|

| a | 1 | 23°C± 2°C | 30% ± 5% | 18°C ± 2°C | 50% ± 5% | 8,0 mm | 8,0 mm | 4,0 mm | Interior doors |

| b | 2 | 23°C ± 2°C | 30% ± 5% | 13°C ± 2°C | 65% ± 5% | 4,0 mm | 4,0 mm | 2,0 mm | Apartment entrance doors to heated stairwells |

| c | 3 | 23°C ± 2°C | 30% ± 5% | 3°C ± 2°C | 85% ± 5% | 2,0 mm | 2,0 mm | 1,0 mm | Apartment entrance doors to heated stairwells, between living areas and unheated rooms (e.g. garages, attic, basement) |

| d | - | 23°C ± 2°C | 30% | -15°C ± 2°C | No requirements | - | - | - | Front/exterior doors (house and portico doors) |

| e | - | 20°C min 30°C max | No requirements | Reference Temperature +55°C ± 5°C | No requirements | - | - | - | front/exterior doors (house and portico doors) - solar radiation |

The standard DIN EN 1121: 2000 describes the different test climates a, b, c, d and e, whereby only climates a-c are relevant for interior doors, climates d and e are relevant for front doors.

Fig.2: Test climates according to DIN EN 1121: 2000 and DIN EN 12219: 1999 and recommended use.

The standard DIN EN 12219: 1999 provides information about the division of doors into one of the four differential climate group classes and defines maximum permissible warpage values.

A correctly specified classification thus includes both the climate class and the test climate used and would be, for example: Class 3 – test climate c -> >short form 3c.

Fig.3: Door leaf deformation of an apartment entrance door with a difference in climatic stress.

Source: ifz info TU-03/2, Seite 1

Damp and Wet Room Doors

Moisture-proof doors are resistant to brief high humidity and occasional splashing water and are used in bathrooms in hotels and hospitals, as well as in private apartments without window ventilation and kitchens.

Wet room doors are designed to withstand even long-lasting high humidity, frequent splashing water and frequent cleaning. They are mainly used in public shower rooms, baths and saunas. Doors made of wood and wooden materials can also be used in damp or wet rooms with a suitable surface coating (e.g. CPL/HPL) and construction (e.g. rustproof fittings).

The testing and classification of the door leaves for the damp/wet room area is carried out according to standard DIN EN 16580: 2015, RAL GZ 426/3. RAL GZ 426/3.

Radiation Protection Doors

Radiation protection doors are used to protect against harmful X-rays, gamma and electron radiation and are mainly used in medical rooms such as X-ray rooms in hospitals or in laboratories.

Radiation protection is achieved through the use of radiation-attenuating lead inserts in the door leaf and, if necessary, the frame. The total thickness of the lead insert (= lead equivalent/attenuation factor according to DIN EN 6113-1) must be specified when planning the system and defined in the radiation protection plan according to DIN 6812, 6846 or 6847.

There are no test requirements or test reports for radiation protection doors, which means that practically any door construction can be converted into a radiation protection door by adding the lead component – provided the construction can bear the additional weight.

Burglary-proof Doors

Burglary-proof doors are classified according to DIN EN 1627 into six different resistance classes >(RC). The higher the resistance class, the higher the resistance and durability of the door element when trying to penetrate violently.

Burglary-resistance classes:

- RC1N – Simple basic security

- RC2 – Standard security

- RC3 – Increased security

- RC4 – high security

- RC5 – High security area

- RC6 – High security area

The areas relevant for normal applications with wood / wood material doors are defined as follows:

| Resistance Class | Offender Type / Behavior | Resistance Time | Application Area |

|---|---|---|---|

| RC1N | Vandalism: Kicking, pressing, jumping against. Little protection against levering. | Not Required | Front door with low burglar resistance. |

| RC2 | Opportunist: Bodily force, simple tools e.g. screwdriver, shim, pliers. | 3 min | Front door and house entrance door with standard risk. |

| RC3 | Opportunist: With add’l second screwdriver and crowbar. | 5 min | Front door and house entrance door with high risk. |

Fig.1: Resistance classes according to DIN EN 1627

The RC2 / RC3 requirements are also achieved among other things like suitable fittings, door hinges and locks.

Thermal Insulation

Heat-insulating door elements help to keep the heat in the home. This is particularly important for front doors.

The U-value, also known as the heat transfer coefficient, describes the heat transfer of the element. The higher the value, the worse the door is insulated. The U-value of house doors is required by law in the Energy Saving Ordinance EnEV 2014 and must correspond to at least U=1.8 W/m²K, that of passive house doors even at least U=0.8 W/m²K.